Procurement Red Flags: How to Spot Issues Before They Become Costly

Tips & Tricks • 3 min read • August 29, 2025 • Written by: Amelia Inskipp

Procurement is one of those functions that quietly keeps a business running. When it works well, nobody notices. But when something goes wrong, it can ripple across the business. Late deliveries, inflated costs, poor supplier performance, or compliance failures can affect everything from operational efficiency to reputation. The challenge isn’t managing procurement but spotting warning signs early enough to prevent small issues from becoming critical.

Lack of Transparency in Supplier Selection

One of the earliest warning signs is a lack of transparency in how suppliers are selected. If there’s little documentation explaining why a particular supplier was chosen, or if the same vendor is repeatedly used without competitive bidding, this can indicate inefficiencies, favouritism, or missed opportunities to get better value. In some cases, it might even mask conflicts of interest. Transparent procurement processes ensure that decisions are traceable, objective, and defensible. At Storm Procurement, we have longstanding partnerships with a vast number of suppliers in order to stay competitive with sourcing strategies that improve visibility and decision-making. By introducing structured evaluations and clear criteria, businesses can ensure every supplier relationship is built on performance and value, not convenience.

Unusual Pricing Patterns

Pricing irregularities are another common red flag. Sudden unexplained price changes or supplier rates that are massively different from market averages should always raise concerns. These patterns may indicate internal management, supplier agreement, or inadequate oversight. Detecting these issues early requires more than just a review. Utilising a procurement risk management framework allows organisations to benchmark costs against market standards, identify anomalies, and track trends over time. This not only prevents overspending but also highlights potential vulnerabilities before they turn into costly mistakes.

Weak Documentation and Record-Keeping

Procurement relies heavily on clear, complete documentation. Missing contracts, unsigned purchase orders, or incomplete records might seem minor at first, but they can have serious consequences when disputing orders or during audits. Poor documentation can hide mistakes and compliance failures. A vigorous contract management process ensures that every purchase order, contract, and approval is recorded, traceable, and stored in a secure, accessible way. Outside of mitigating risk, strong documentation also improves operational efficiency, allowing teams to respond quickly to issues and maintain accurate reporting.

Supplier Dependence

Relying too heavily on a single supplier is another hidden risk. While it may feel efficient to centralise procurement with a trusted vendor, over-dependence increases vulnerability to supply disruptions, price hikes, or service failures. Conducting a supplier risk assessment provides visibility into these dependencies, allowing organisations to expand their sourcing strategies and build contingency plans. Differentiating suppliers isn’t about replacing trusted partners, it’s about ensuring resilience and protecting operations from unexpected shocks.

Conflicts of Interest

Internal issues are equally important to watch for. Employees who have personal ties to suppliers, or staff who regularly bypass standard approval processes, can create conflicts of interest that put the company at risk. These situations don’t always involve intentional wrongdoing; sometimes they result from unclear policies or a lack of oversight. However, without strong procurement controls, even small lapses can escalate into costly failures. Making sure that all procurement decisions are transparent, documented, and aligned with business policies protects both the company and its employees.

Recurring Delivery or Quality Problems

Finally, persistent issues with delivery times or product quality could mean problems with supplier performance management. Late shipments, inconsistent quality, or ongoing complaints may initially appear as one-off incidents, but repeated occurrences could indicate deeper issues. Regular supplier performance reviews and clearly defined KPIs help organisations monitor reliability and address concerns before they affect operations. By actively engaging with suppliers and tracking performance over time, businesses can improve accountability, strengthen relationships, and ensure that contract expectations are consistently met.

Procurement challenges rarely appear overnight. They often develop slowly, hidden in small patterns of behaviour, pricing, documentation gaps, or supplier dependencies. Spotting red flags early requires vigilance, structured processes, and the right systems in place to monitor risk. Organisations that take a proactive approach, from implementing competitive sourcing strategies to supplier performance management, are not only protecting themselves from potential losses but also positioning procurement as a growth strategy.

Related Articles

Business News

Business Trips - November

Industry Insights

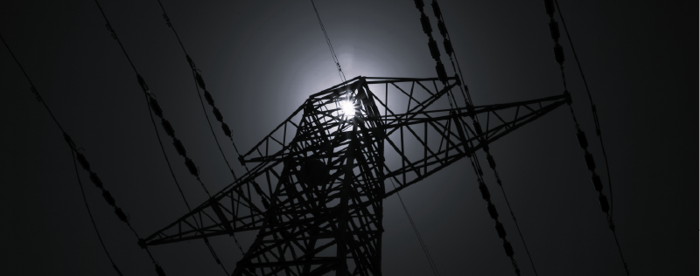

The Iberian Peninsula Blackout: Lessons in Emergency Procurement

Don't Miss Out On Our Updates

Sign up and Join Our Newsletter Today