Mining Processes: Placer Mining

Business News • 3 min read • Feb 7, 2023 9:08:59 AM • Written by: Amelia Inskipp

Mining is the process used to obtain valuable resources from the Earth. This is done to acquire supplies that cannot be produced or manufactured through artificial methods. There are numerous techniques to extract these materials. The most commonly used procedures are underground mining, surface mining, placer mining and in-situ mining.

We have previously discussed both underground mining and surface mining in previous posts. In this post, we explore placer mining and the processes of extracting materials through this method.

Placer Mining Methods

Placer mining is a method of separating minerals from hard gravel or sand. This method differs from hard rock mining as hard rock mining extracts the veins of materials from solid rock. There are several different types of placer deposits, but the most commonly extracted locations are stream and beach placers, as they are surrounded by running water. The particular methods used are dependent on the mine due to a number of factors such as the thickness of the deposit and the quantity of water available.

Panning

The most basic kind of placer mining is the use of a prospector's pan to separate the sediment-filled water from the sought-after material. Since gold weighs more than sand, the gold remains in the pan whilst the other residue spills out. Many of the materials include gold, tin, and gemstones. Using a prospector's pan is the foundation for all placer mining techniques. Today, panning is rarely used if mining is for monetary reasons due to the lengthy process it takes. On average, mining a cubic yard of gold takes around 10 hours, so for this reason many other methods are used for industrial purposes.

Sluice Box

Another method is the use of a sluice box. A sluice box is a durable box, with an open top and bottom, toughened by a set of riffles. Water and placer deposit is placed in the box, and as it flows down the ripples agitate the water, preventing the lighter material from settling, and retaining the valuable material. The sluice box was used heavily in the California gold rush for larger-scale operations. As sluicing is only effective in areas where there is a sufficient water supply other variations of extraction are used.

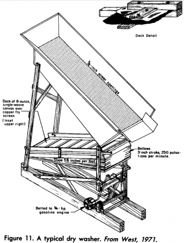

Dry Washing

Dry-washing is the method that involves placing gravel on a riddle board with bellows placed underneath it. The bellows are then used to blow air through the board to separate the lighter materials such as sand and dirt from the goal. In comparison to panning, four cubic yards can be processed in a day.

Gold Dredge

For large-scale sifting from large volumes of deposits, the use of mechanical dredges is employed. Dredges were originally large boats with the ability to process large amounts of material. Smaller dredges are now commonly used and operate by sucking water and gravel up through long hoses where the gold can then be separated using more traditional methods.

Although mining in general has a significant impact on the environment, placer mining has a much more environmentally friendly approach than surface mining. This is because of the sediment returning to the water after extraction.

Reach the World. Giving Made Easy with Impact.

Amelia Inskipp

Related Articles

Business News

Mining Processes: Underground Mining

Business News

Mining Processes: Surface Mining

Tips & Tricks

Mining Industry- The Last Decade

Don't Miss Out On A Thing

Sign up and Join Our Newsletter Today