Preparing for Supply Chain Crisis

Tips & Tricks • 3 min read • Apr 19, 2022 9:04:56 AM • Written by: Amelia Inskipp

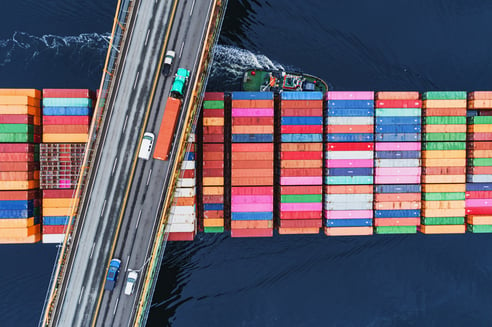

In the past year alone, we have had multiple strains on the global supply chain. Long gone are the times when canal blockages causing standstills to billions of pounds of commodities were treated as one-off events. The pandemic has hugely affected the efficiency of the global supply chain but combined with the ongoing conflict in Ukraine and trade wars between China and the US, the efficiency of the supply chain is being hit more than ever before.

Preparing For Supply Chain Crisis

The uncertainty of these extremities is not something we can stop or avoid and is essentially impossible to plan for as they are damaging in different ways. And with some experts saying it could take until 2024 for supply chains to resume as ‘normal’ there needs to be measures put in place to somewhat prepare if calamity does occur.

The current supply chain model is built on the premise of things running efficiently, and once a problem occurs, it can create a ripple effect.

Lead Times

Lead times and the turnaround for companies to deliver are critical in the running of a business and the ongoing supply chain crisis poses a huge threat to this. Customers now expect deliveries at the drop of a hat with companies offering next day delivery and even Amazon offering same-day delivery. However, for global supply chains, it can take weeks, even months for goods to be shipped and transported overseas without any disruptions.

Lead times have doubled compared to what they were at the beginning of 2020. For China, lead times increased by 222%, Europe by 201% and the US by 200%. This not only leaves companies with material shortages but also instances of running out of merchandise completely.

Brexit has also caused UK manufacturers and companies significant burdens. With the EU being the UK’s largest trade partner Brexit has led to additional admin and border delays. This not only means longer lead times but also creates an increase in prices for import tariffs.

Both the pandemic and Brexit have led to shortages in HGV drivers, resulting in again, much longer lead times and even in some cases cancellations in orders from manufacturers. We have previously written a blog post about the shortage of HGV drivers and the effect this has.

Lead times are always tricky to manage as these are what are most prone to blips.

The obvious answer to solving lead times is to supply from local suppliers as distance and shipping delays are two big factors in the wait for supplies. Finding local suppliers can help cut both of these factors. However, although transportation is cut significantly, the prices of goods are usually considerably more expensive in comparison to overseas suppliers. Companies need to find a balance of the cost of goods relative to the lead times to see what will benefit your supply chain and ultimately your customer more.

Another way the ease of lead times can be assisted is by purchasing orders little and often. Although bulk ordering can be more cost-friendly, lead times are often extended to keep up with demand. Therefore, ordering in less but more frequent will definitely shorten lead time and therefore make supply management more efficient.

Reliability

As supply chains are complex, many buyers are tied into lengthy contracts which limits them to obtaining supplies from alternative sources. The over-reliance on other countries' supplies also leaves more room for supply chains to crash as their only source is void.

This has been evident from the ongoing conflict in Russia. Russia is a major exporter of some of the world’s most important commodities and the significant power that they have means it can influence other nations' security and economic interest.

The reliance that countries have on Russian exports has left shortages in essential items. Europe relies heavily on Russia for natural gas and crude oil and both Russia and Ukraine account for more than 25% of the world’s wheat trade.

Furthermore, oil and gas prices are rocketing already due to global incidents, Russia is creating even more disruptions due to the power they hold. It is not just other nations that rely heavily on their oil and food supplies but also Asia relies heavily on Russia’s transportation infrastructure. And with air freight prices being significantly more expensive, other considerations are needed to be put in place for businesses to not fall short.

As most businesses were not prepared for the pandemic, it has equipped companies to implement proper risk management tools so events such as the pandemic and the crisis of the war in Ukraine have left to don’t allow inflation of pressure onto key commodities.

For global supply chains not to fall apart it is also time for businesses to start to seek alternative sources of supply. For some companies that have single-source suppliers, it is key for them to pursue new, secondary supplier relationships ensuring they are not jeopardising their business by solely relying on one supplier.

Although we are currently in uncertain times it is even more evident that having a business strategy and plan to prepare for occurrences like this is key. Also having skilled procurement and supply professionals is critical to survive in this industry and navigate through these times.

Reach the World. Giving Made Easy with Impact.

Amelia Inskipp

Related Articles

Tips & Tricks

Understanding your Workplace Signs

Tips & Tricks

Checking your Hard Hat Expiry Date

Business News

Oil and Gas Trends

Don't Miss Out On A Thing

Sign up and Join Our Newsletter Today